Dia 6

Basic Info.

| Model NO. | 6150 |

| Process | Eaf+Lf+Vd+Forged+Heat Treatment(Optional) |

| Technology | Hot Rolled/ Forged/ Cold Drawn |

| Form | Round Bars/ Flat Bar / Blocks/ Tube |

| Test | Ensile Strength, Yield Strength, Elongation |

| Certificate | ISO/ Mill Certificate |

| Ut Standard | Sep 1921-84 D/D |

| Surface | Black; Peeled; Polished; Machined; Grinded; Turne |

| Heat Treatment | Normalized;Annealed ;Quenched ;Tempered |

| Ex-Stock | No |

| Non-Metallic Inclusiton | ASTM E45 |

| Grain Size | ASTM E112 |

| Payment Term | 30% Tt Deposit, Balance Against Bl Copy |

| Delivery Date | 30 Days |

| Length | 3000-5800mm |

| Transport Package | Seaworthy Package |

| Trademark | Qilu |

| Origin | China |

| HS Code | 7228400000 |

| Production Capacity | 400, 000ton/Year |

Product Description

GB 50CrVA | JIS SUP10 | DIN 51CrV4 | ASTM 6150 Spring Steel

- Quick Details

1: 6150 steel introductionAISI 6150 steel is chromium vanadium type spring steel. It's a similar alloy steel to 5150 steel with small, but effective, vanadium addition, to import greater hardness. AISI steel 6150 has low distortion properties and is easily heat treated. The SAE 6150 steel grade is suitable for oil hardening and tempering.

2: 6150 Steel equivalentCountry Japan BS China USA Standard JIS G4801 EN 10083 GB/T 3077 ASTM A29 Grade SUP10 1.8159/51CrV4 EN31/535A99 6150

3: 6150 steel chemical compositionGrade C Si Mn P S Cr V Ni 6150 0.48-0.53 0.15-0.35 0.7-0.9 0.035 0.040 0.8-1.1 0.15 / 1.8159 0.47-0.55 0.4 0.7-1.1 0.025 0.025 0.9-1.2 0.1-0.25 / SUP10 0.47-0.55 0.15-0.35 0.65-0.95 0.030 0.030 0.8-1.1 0.15-0.25 / 50CrVA 0.47-0.54 0.17-0.37 0.5-0.8 0.030 0.030 0.8-1.1 0.1-0.2 /

4: 6150 steel mechanical propertiesThe mechanical properties mainly include tensile strength, yield strength, elongation, area or reduction, hardness, impact value, non-metalic inclusion etc. Different heat treatment, the mechanical properties will be different, such as normalized, tempered, QT. If you want to know the properties, kindly contact the salesman.

5: 6150 steel overviewsSize Round Dia 6-1200mm Plate/Flat/Block Thickness

6mm-500mmWidth

20mm-1000mmHeat treatment Normalized ; Annealed ; Quenched ; Tempered Surface condition Black; Peeled; Polished; Machined; Grinded; Turned; Milled Delivery condition Forged; Hot rolled; Cold drawn Test Tensile strength, Yield strength, elongation, area of reduction, impact value, hardness, grain size, ultrasonic test, US inspection, magnetic particle testing, etc. Payment terms T/T;L/C;/Money gram/ Paypal Trade terms FOB; CIF; C&F; etc.. Delivery time 30-45 days Application 6150 spring steels are used for heavily stressed machinery parts including shafts, gears, pinions and also in hand tool components. ASTM 6150 steel is also widely in the motor vehicle industry AISI 6150 is suitable for many general engineering applications that require high tensile strength and toughness 6. ASTM 6150 Steel Heat Treatment

Preheat:

1200-1250F (650-675oC), equalize.

Annealing:

1100-1300F (595-740oC), hold 2 hours, air cool. As with 5150 alloy, the microstructure for this 6150 alloy steel to give optimum machinability is one of coarse lamellar pearlite to coarse spheroidite.

Normalizing:

A nominal normalizing temperature for the 6150 spring steel is 1650oF (900oC.) This treatment is followed by air cooling.

Straightening:

Best done warm 400-800F (205-425oC).

High Heat:

1550-1650F (845-900oC), soak 10 to 30 minutes. For vacuum hardening, use the high side of the high heat range and soak times.

Quenching:

Oil quench to hand warm, 150F (65oC). Temper SAE 6150 steel immediately. Note vacuum furnaces must have oil quench capability.

Tempering:

Tempering at 400-1200 (205-650oC) for 1 hour per inch (25mm) of thickness at temperature is recommended. (2 hours min.). Air cool to room temperature. Tempering of the AISI 6150 grade steel will be between 400-600°C for most applications.

7: Delivery condition

For hot rolled bar, usually the delivery condition is hot rolled, annealed, Black surface.

For hot rolled sheet, usually the delivery conditon is hot rolled, annealed, black surface.

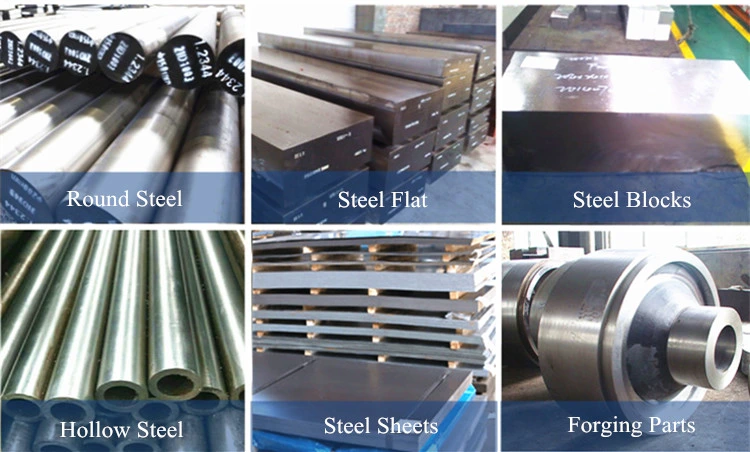

1: Main Product:

| GB GB/T 1299 | JIS JIS G4404 | DIN (W-Nr.) DIN EN ISO4957 | AISI/ASTM ASTM A681 | BS BS 4659 |

| Cold Work Tool Steel | ||||

| Cr12 | SKD1 | 1.2080/X210Cr12 | D3 | |

| Cr5Mo1V | SKD12 | 1.2363/X100CrMoV5 | A2/T30102 | BA2 |

| Cr12MoV | 1.2601 | D5 | ||

| Cr12Mo1V1 | SKD11 | 1.2379/X153CrMo12 | D2 | |

| X210CrW12 | SKD2 | 1.2436 | D6 | |

| 9CrWMn | SKS3 | 1.2510/100MnCrW4 | O1 | |

| 9Mn2V | 1.2842 / 90MnCrV8 | O2 | B02 | |

| 5CrNiMo | SKT4 | 1.2713 | L6/T61206 | BH224/5 |

| Hot work Tool Steel | ||||

| 1.2355/50CrMoV13-15 | S7/T41907 | |||

| 5CrNiMoV | 1.2714 | 6F3 | ||

| 5CrNi4Mo | 1.2767 | 6F7 | ||

| SKD7 | 1.2365/32CrMoV12-28 | H10/T20810 | BH10 | |

| 4Cr5MoV | SKD6 | 1.2343/X37CrMoV5-1 | H11/T20811 | BH11 |

| 4Cr5MoSiV1 | SKD61 | 1.2344/X40CrMoV5-1 | H13 | |

| SKD62 | 1.2605/X35CrWMoV5 | H12/T20812 | BH12 | |

| 3Cr2W8V | SKD5 | 1.2581 | H21 | |

| Plastic Mould Steel | ||||

| 3Cr2Mo | 1.2311 | P20 | ||

| NAK80 | 1.2312 | P20+S / P21 | ||

| 3Cr2MnNiMo | 1.2738 | P20+Ni / 718 | ||

| 4Cr13 | SUS420J2 | 1.2083 | 415 | |

| 3Cr17+S | SUS420F | 1.2085 | ||

| 3Cr17Mo | SUS420J | 1.2316 | ||

| Engineering Steel | ||||

| GB GB/T 699 | JIS JIS G4051 | DIN (W-Nr.) EN 10083-2 | AISI/ASTM ASTM A20 | EN / BS |

| 1018 | EN2C | |||

| 20 | S20C | C20/1.1151 | 1020 | EN3B /070M20 |

| S35C | C35 | 1035 | ||

| 1040 | EN8/080M40 | |||

| 45 | S45C | C45/1.1191 | 1045 | EN8D/C45E |

| 50 | S50C | 1050 | ||

| S55C | 1055 | EN9/070M55 | ||

| Q345 | S355/ST52-3/1.1170 | EN14/150M19 | ||

| GB GB/T 3077 | JIS JIS G4105/JIS G4103 | DIN (W-Nr.) EN 10250 | AISI/ASTM ASTM A29 | BS BS 970 |

| 40Cr | SCr440 | 41Cr4(1.7035) | 5140 | |

| SCM420 | 18CrMo4/1.7243 | 4118 | ||

| 30CrMo | SCM430 | 25CrMo4/1.7218 | 4130 | 708A25/708M25 |

| 42CrMo | SCM440 | 42crmo4/1.7225 | 4140 | EN19/709M40 |

| 4145 | ||||

| 4330 | ||||

| 40CrNiMoA | SNCM 439/SNCM8 | 36CrNiMo4/1.6511 | 4340 | EN24/817M40 |

| 40NiMoCr10-5/1.6745 | EN26 | |||

| 34CrNiMo6 / 1.6582 | 4337 | |||

| 30CrNiMo16-6/1.6747 | EN30B/835M30 | |||

| 32CrMo12/1.7361 | EN40B/722M24 | |||

| SCM415 | 16MnCr5 / 1.7131 | 5115 | ||

| 15CrNi6/1.5919 | 3115 | |||

| 16NiCr4/1.5714 | EN351/635M15 | |||

| 4615/4617 | EN34/665M17 | |||

| 14NiCr4/1.5752 | 3310/3415 | EN36/655M13 | ||

| 15NiCrMo16-5/1.6723 | EN39/835M15 | |||

| 18CrNiMo7-6 (1.6587) | 4815 | |||

| SNCM220 | 1.6523/21NiCrMo2 | 8620 | 805M20 | |

| 20CrNiMo5 | EN353 | |||

| GCr15 | 52100/1.3505 | EN31/535A99 | ||

| Stainless Steel | ||||

| SUS440C | X105CrMo17/1.4125 | S44004/440C | ||

| Wear-resisting Steel | ||||

| GB | JIS | DIN (W-Nr.) | AISI/ASTM | SSAB |

| NM400 | HB400 | |||

| NM500 | HB500 | |||

| Spring Steel | ||||

| GB | JIS | DIN (W-Nr.) | AISI/ASTM | SSAB |

| 65MN | 1066 | |||

| 60Si2Mn | SUP6 | 60Si7 | 9260 | |

| 60Si2MnA | SUP7 | 60Si7 | 9260 | |

| 55CrMnA | SUP9 | 55Cr3 | 5155 | |

| 60CrMnA | SUP9A | 5160 | ||

| 50CrVA | SUP10 | 51CrV4 | 6150 | |

| High Speed Steel | ||||

| GB | JIS JIS G4403 | DIN (W-Nr.) DIN EN ISO 4957 | AISI/ASTM ASTM A600 | BS BS 4659 |

| SKH51 | 1.3343 | M2 | ||

| SKH55 | 1.3243/HS6-5-2-5 | M35 | ||

| SKH59 | 1.3247/HS2-9-1-8 | M42 | ||

| SKH2 | HS18-0-1/1.3355 | T1 | ||

| SKH3 | S 18-1-2-5/1.3255 | T4/T12004 | ||

| SKH4 | 1.3265/S18-1-2-10 | T5/T12005 | BT5 | |

| All kinds of forging parts according to Drawing | ||||

2: Qilu steel overviews

| Size | Round | Dia 8-1200mm |

| Plate/Flat/Block | Thickness 10mm-800mm | |

| Width 20mm-2000mm | ||

| Heat treatment | Normalized ; Annealed ; Quenched ; Tempered | |

| Surface condition | Black; Peeled; Polished; Machined; Grinded; Turned; Milled | |

| Delivery condition | Forged; Hot rolled; Cold drawn | |

| Test | Tensile strength, Yield strength, elongation, area of reduction, impact value, hardness, grain size, ultrasonic test, US inspection, magnetic particle testing, etc. | |

| Payment terms | T/T;L/C;/Money gram/ Paypal | |

| Trade terms | FOB; CIF; C&F; etc.. | |

| Delivery time | 30-45 days | |

Hunan Qilu Industrial Co., Ltd were already engaged in exporting steel for 11 years, could supply a great variety of hot forged, hot rolled and cold drawn Steels, including engineering steel, cold work tool steel, hot work tool steel, plastic mold steel, spring steel, high speed steel, stainless steel etc., besides Qilu Industrial also has their own heating treatment shop and machining shop to provide heating and cutting service.

Since 2008 year, Hunan Qilu Industrial has the right to export all FORGED STEEL behalf of Qilu Speical Steel Co.,ltd which is specialized in smelting and forging of special steel since 1965 year, now Qilu special steel is one of the biggest manufacturer of forged product in China.The forged products are used in Automotive, Aerospace, Power Generation, Oil & Gas, Transportation and Industrial. We already set up the warehouse in Wuxi and Dongguan city, more than 20000 tons ex-stock could be supplied with kinds of size.

Qilu Industrial is the professional one-stop steel manufacturer, stockist and exporter in China, our customers spread all over the world, include West Europe, North America, South America, Asia, Middle Asia, Africa, Australia, etc.

The company owns advanced special steel smelting facilities and forging processing equipments, the main steel-making equipment include 2 sets of 50t ultra-high power electric arc furnaces,2 sets of 60t LF refining furnaces,1 set of 60t vacuum degassing refining furnace and 4 sets of 1-20t electroslag re-melting furnaces.The main forging equipments mainly include:3 sets of 5t electro-hydraulic hammers, 1 set of high-speed forging units of 800t,1600t,2000t and 4500t respectively.

Summer Ning Hunan Qilu Industrial CO., LTDWeb: qilusteel.en.made-in-china.com .